New Digital Technologies, Industry 5.0, Sustainability, Rights, Quality of Life; the EU’s Holistic Vision for its Citizens

TANGO, Digital Technology for Secure and Trustworthy Data Flows, is an advanced Horizon research project in line with the EU's strategic framework. "Europe faces a triple imperative to protect, prepare and transform, in its quest for building forward better, after the Deadliest pandemic of the past century and for building forward better to address the greatest challenge humanity has ever faced - climate change and biodiversity collapse. An enormous challenge: how to transform human life quickly enough to enable 8 billion people to live sustainably and peacefully within planetary boundaries? While Europe cannot face this challenge alone, we believe it can lead the global community towards the deep Systemic transformation that this and next decades will inevitably require."

This is how the European Commission expresses itself in the strategic document made public in January 2022, titled “Industry 5.0., a Transformative Vision for Europe - Governing Systemic Transformations Towards a Sustainable Industry”. This document expresses the European Union’s vision of strategic prospects for economic and social development in the light of the new challenges posed by climate change and new technologies still to be implemented.

In order to understand the core of this programmatic document, it is necessary to understand what Industry 5.0 stands for.

The term "Industry 5.0" first appeared in a 2015 article in Linkedin. Its author is the Czech industrial entrepreneur, Michael Rada; he claims that "we need to return to the centrality of the environment and people in the industrial process".

A further contribution to clarifying the concept of, appears in 2016 when the Association of Japanese Industrialists states that Industry 5.0 develops in "a society that seeks to balance economic development with solving socio-environmental problems, in which technologies are used not only for profit, but to improve the quality of life of every citizen."

In 2018 the Danish Esben Hallundbæk Østergaard, CEO and co-founder of REInvest Robotics, co-inventor of cobot UR, founder of Universal Robots (market leader within collaborative cobots robots), intervenes in the debate on Industry 5.0 in the journal International Society of Automation, drawing attention to Industry 4.0. According to him, we run the risk of wasting human creativity, problem solving and critical thinking by speeding up the transfer of major industrial sectors from human labour to robots. A real failure with regard to the great opportunity to achieve mass customizations made possible by Industry 4.0. So, why not move one-step further and strongly support industry 5.0? Østergaard strongly backs a necessary return of the "human touch" in the production processes.

The European Commission's 2022 report comes at the end of a long conceptual process and must be considered as part of a broader and forward-looking strategy on society, industry and technology: the regulation on artificial intelligence, the Green Deal, the industrial strategy, the skills agenda and the action plan for digital education. A 360-degree vision.

This is an outcome of a lengthy process that involves extensive consultation and the participation of a broad audience of stakeholders.

The document “Industry 5.0 - Towards a Sustainable, Human-Centred and Resilient European Industry” took shape following a series of discussion tables that took place in two virtual seminars organised in June 2020. All the participants agreed with the same opinion about the urgent need to better integrate the European Union’s social and environmental priorities with the most advanced developments in technological innovation, turning the individual approach to technology into a systemic perspective. These meetings involved research, technology organisations and financial agencies across Europe.

To understand what is happening in the industrial evolution from 4.0 to 5.0, it is perhaps useful to emphasize that it is not enough to use the latest (enabling) technologies more efficiently within the production process, but to change paradigm. Technology, including enabling technology, must be widely used, while considering respect for human rights and the environment as essential support to address major geopolitical changes and natural disasters caused by climate change. The debate has shifted from focusing on production processes to focusing on human well-being, sustainability and resilience.

It is clear that Industry 5.0 is neither an evolution of Industry 4.0 nor an alternative paradigm for its destruction. To better understand, we can briefly examine the evolutionary trajectories that characterized Industry 4.0.

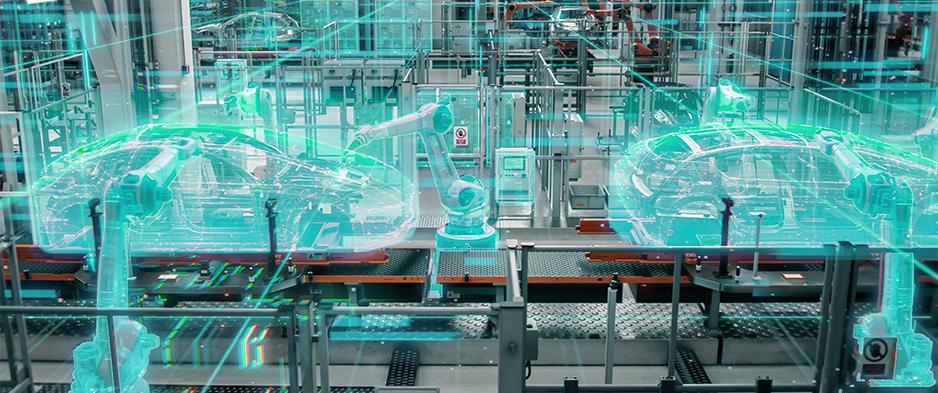

To put it in another way, if Industry 4.0 is based on the interconnectivity between machines and computer systems, Industry 5.0 seeks to combine the roles of people and machines so that they can strengthen and be complementary: hence Industrial 5.0 supports sustainable robotics.

Within Industry 5.0, technology remains a key component of production processes. What is changing is the humanistic approach that focuses its attention on the human being, his rights, and the environment in which he lives, only after productive needs.

The relationship between man, technology and the production processes in which he was inserted has been constantly asymmetric. Man was imprisoned by the times and rules of machines imposed by the production process.

The first revolution was born thanks to the introduction in the production processes of the steam engine at the end of 1700, and then the second came at the end of 1800, in which chemistry and electricity allowed the production of mass consumption goods. In the age of 3.0 (in the 1970s) the focus was on automation through electrical engineering and information technology. The fourth industrial revolution is based upon the Internet of Things and Real-Time Data Communication for a ubiquitous factory, physical and virtual at the same time.

According to the European Commission, the fourth industrial revolution has focused too much on the digitalisation of production processes, and the use of artificial intelligence to increase productivity and efficiency, marginalising the role of workers involved in the productive fabric, and the transition to more sustainable development models.

For the fifth industrial revolution to have its full impact, at least six elements, representing the strategic strengths, must be fulfilled: 1) Individualized human-machine interaction. 2) Bio-inspired technologies and intelligent materials.3) Digital Twins and simulation. 4) Transmission, storage, and analysis technologies. 5) Artificial intelligence. (AI). 6) Technologies for energy efficiency: the use of renewable technologies, storage, and autonomy.

These six elements represent the strategic strengths that will allow the current economy to advance towards the goals of Industry 5.0.

The potentialities of this new combination of technology and human centrality are enormous and still unexplored. It can offer powerful tools to strengthen resilience in various areas. It is enough to reflect on the advantages that can arise from the possibility of foreseeing probable risks, such as changes in time or changes in demand in a specific market. Predictive Analytics Predicts Multiple Risks to Strengthen Industry Resilience.

Industry 5.0 is still in its formative stages while the actors of the economy and politics are still immersed in the effort to optimize industry 4.0, using the existing technologies on the market. However, the aim is to promote a more resilient, sustainable and humane industry.

Revolution 5.0 promises to benefit a much broader population: the goal is to be beneficial for workers, companies, and our planet at the same time. In these times of paradigm shift, we seek not just efficiency and productivity, but a way of producing that respects the limits of our planet while valuing people.

The creation of new job opportunities for many unemployed people, affected by the technological factor in the old labour market throughout Europe, requires a determined effort on the part of the Commission.

A study by Deloitte on the prospects for the European labour market and the shortage of skilled workers gives us pause for thought: over the next decade, 3.4 million jobs will be created, with just 1.4 million skilled workers ready to work.

Industry 5.0 uses new technologies to make workplaces safer and more inclusive, to help workers better control, and manage the burnout risks associated with digital work, to reduce environmental impact. The fifth revolution aims to use artificial intelligence in a different way without compromising the dignity of the working person. Robots are perfectly compatible with many of these roles, and cobots can work side by side with workers. Cobots are useful because they can take on mundane, repetitive and dangerous tasks while workers move into high value positions.

Automation gives companies a competitive edge with higher and more consistent product quality, increased production and lower overall costs. If we take into account only one production sector, the food sector, robots are expected to create 70,000 to 90,000 jobs in the world over the next four years.

Revolution 5.0 is by no means a phenomenon of nature. It needs the political will of the people, in particular the political representatives of the European states and the EU institutions, as well as the entire civil society of our continent. Without the proper support of scientific research capabilities to explore previously unknown worlds, even with the best of intentions, they will hardly become a reality. TANGO, together with other Horizon projects, will certainly play its part.